Friction impeded countless processes, from everyday tasks to complex industrial operations. This persistent force operates as a obstacle, converting kinetic energy into warmth. Lubricants stand as the solution in this conflict, dramatically minimizing friction and optimizing efficiency.

They achieve this feat by creating a delicate film between components. This coating layer impedes the direct collision of elements, thereby mitigating friction.

There is a diverse range of lubricants, each optimized for particular applications. Oils, greases, and solid lubricants are commonly employed, with their properties varying based on the performance environment.

Exploring Beyond Oil: Advanced Lubricant Technologies

As the world transitions towards sustainable practices, the need for cutting-edge lubricant technologies has never been greater. Traditional oil-based lubricants, while robust, have significant sustainability impacts. This motivates researchers to develop next-generation solutions that offer superior performance while minimizing negative effects on the planet.

A wide range of alternative lubricants is coming to the forefront, each with its own unique advantages. Bio-based lubricants, derived from renewable sources like plants and algae, offer a viable solution. Synthetic lubricants, engineered for enhanced performance, provide outstanding resistance to wear and tear.

Furthermore, nanotechnology is revolutionizing the lubricant industry by introducing nanoparticles into base oils. This boosts lubrication properties, leading to increased productivity and reduced friction.

The future of lubrication is bright, with ongoing research constantly pushing the boundaries of what's here feasible. As we strive for a more sustainable future, advanced lubricant technologies will play a essential role in driving progress across various industries.

Keeping Things Moving: Lubricants in Industrial Applications

In the demanding world of industrial processes, where machinery operates continuously under high stress, proper lubrication is essential. Lubricants serve as a barrier against abrasion, reducing heat generation and providing smooth operation. From the intricate mechanisms of automotive engines to the colossal gearboxes of heavy equipment, lubricants play a crucial role in optimizing performance, increasing component life, and preserving equipment reliability. The right lubricant for a specific application can significantly impact efficiency, productivity, and overall operational success.

- Proper lubrication selection is crucial for maximizing equipment lifespan.

- Lubricants reduce wear and tear, minimizing maintenance requirements.

- Different industrial applications demand specific lubricant properties.

Maintaining Your Machinery with Lubrication: A Simple Guide

Proper lubrication is crucial for the smooth and efficient operation of any machine.

By consistently applying lubricant to moving parts, you can significantly reduce friction, wear and tear, and extend the lifespan of your equipment. A simple lubrication schedule will help prevent costly repairs and downtime.

Here are some key points to remember:

- Refer to the manufacturer's guidelines for specific lubricant types and application frequency.

- Examine moving parts regularly for signs of wear or damage, such as roughness or excessive noise.

- Employ a variety of lubrication methods, including manual, depending on the application.

- Store lubricant in a clean and dry location to prevent contamination.

By

The Future of Friction Reduction: Nanotechnology in Lubricants

Nanotechnology is poised to transform the world of lubricants, leading to unprecedented reductions in friction and wear. By incorporating nanoparticles into traditional lubricant formulations, engineers can create films at the nanoscale that dramatically improve performance. This has significant implications for a wide range of applications, from manufacturing to biotechnological sectors.

The use of nano-lubricants can significantly reduce friction between moving parts, leading to increased lifespan. Moreover, nanotechnology allows for the design of lubricants that are adaptive, able to repair themselves under stress and maintain optimal performance.

- Research in this field continue to advance rapidly, exploring novel materials.

- As a result, the future of friction reduction looks bright, with nanotechnology paving the way for a new era of performance in various industries.

Sustainable Solutions: Eco-Friendly Lubricants for a greener Tomorrow

As we stride towards a future focused on environmental responsibility, the need for eco-friendly alternatives has never been greater. This includes various sectors, with the lubricant industry at the forefront of this evolution. Traditional lubricants often contain harmful chemicals that can contaminate our ecosystems and pose risks to human health. However, a new era of environmentally friendly lubricants is emerging, offering high-performing lubrication while minimizing their impact on the environment.

- Moreover, these eco-friendly lubricants are often biodegradable, ensuring they break down naturally without leaving a lasting footprint on our planet.

- Via utilizing these cutting-edge lubricants, we can minimize our dependence on existing petroleum-based products and pave the way for a more eco-conscious future.

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Shane West Then & Now!

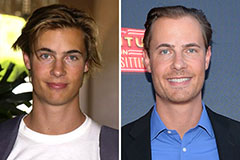

Shane West Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!